In the ever-evolving world of textiles, new and innovative materials continue to emerge, offering unique properties and applications. One such material that has gained attention in recent years is toothbrush yarn. While the name might conjure images of dental care, toothbrush yarn is, in fact, a versatile textile fiber with applications ranging from home furnishings to fashion, and even industrial uses.

The production of toothbrush yarn involves several key steps that are essential to ensure the quality and versatility of the fiber:

The process begins with polyester resin, which is melted and extruded into thin filaments. The material is chosen for its durability, softness, and ability to retain its shape after processing.

The polyester filaments are then spun into fine fibers using a process called drawing, where the fibers are stretched to increase their length and improve their strength. This step also enhances the smoothness of the fibers, contributing to the yarn’s softness and flexibility.

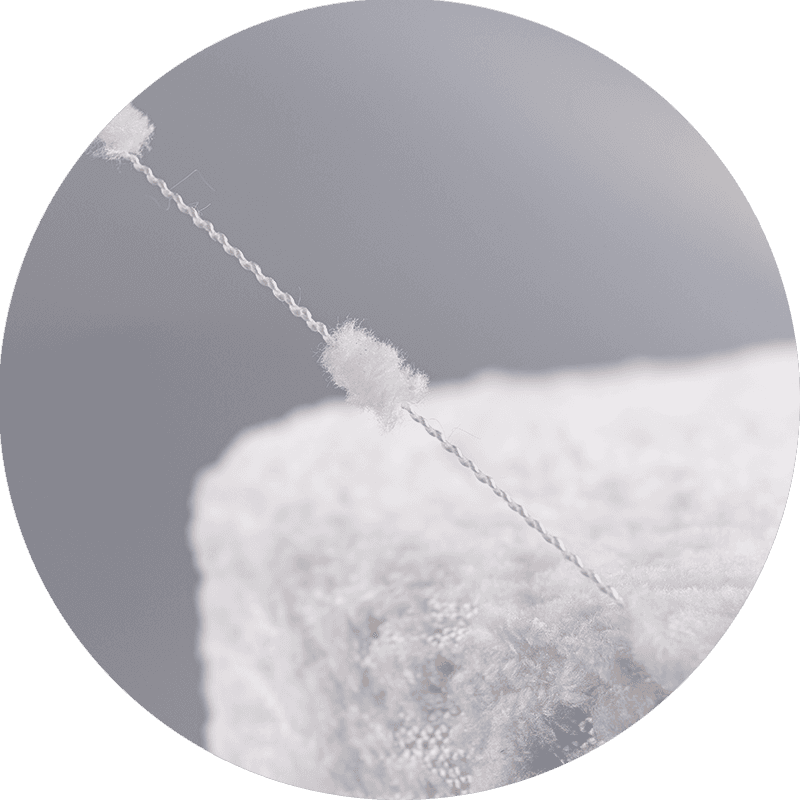

Texturizing is a critical step in the production of toothbrush yarn. The fibers are twisted and crimped to give them a unique texture and appearance. This process can also be used to create different thicknesses of yarn, depending on the desired application.

After texturizing, the yarn undergoes finishing treatments to enhance its properties. These treatments may include dyeing, softening, or adding chemical coatings to improve the yarn's performance in specific applications, such as resistance to moisture or UV light.

Finally, the yarn is wound onto spools and ready for use in the production of various textile products.

Toothbrush yarn’s combination of softness, strength, and flexibility makes it a versatile material suitable for various industries and applications. Some of the most common uses include:

Toothbrush yarn is primarily used in the textile industry for making fabrics and garments. It is often woven or knitted into fabrics for items such as T-shirts, jackets, and activewear. The yarn’s softness and smooth texture provide a comfortable feel, while its durability ensures the fabric holds up well after repeated use and washing.

Toothbrush yarn is also widely used in the production of home furnishings. It is often found in the manufacturing of upholstery fabrics, cushions, and even bedding materials. The yarn’s strength and flexibility make it an excellent choice for creating long-lasting, comfortable, and aesthetically pleasing textiles for home use.

One of the most significant applications of toothbrush yarn is in the production of flooring materials, including carpets and rugs. Due to its resilience and ability to withstand heavy traffic, toothbrush yarn is ideal for use in residential and commercial carpets. It is also commonly used in mats, rugs, and other flooring accessories, where it adds both durability and a plush texture.

In addition to its use in consumer products, toothbrush yarn is increasingly being used in industrial applications. It can be woven into specialized fabrics for use in automotive interiors, protective clothing, and filtration systems. Its ability to withstand high temperatures, resist moisture, and offer a soft yet durable structure makes it an ideal material for technical textiles that require a combination of strength and comfort.

Toothbrush yarn is also gaining traction in the growing market for eco-friendly textiles. Made from recycled PET plastic, it offers a sustainable alternative to conventional yarns made from virgin materials. Manufacturers are increasingly turning to toothbrush yarn for products like bags, accessories, and even shoes, tapping into the demand for environmentally conscious materials.

The softness and unique texture of toothbrush yarn also make it an excellent material for fashion accessories. It is often used in the production of scarves, hats, handbags, and jewelry. The yarn’s ability to hold color and its smooth texture give accessories a premium look and feel, while its durability ensures that these products maintain their shape over time.

Another notable application of toothbrush yarn is in the production of towels and cleaning wipes. The yarn's softness makes it highly absorbent, ideal for use in towels, wipes, and other bath textiles. The fine fibers allow for effective cleaning while remaining gentle on the skin, making it a popular choice for luxury bath products.

The growing popularity of toothbrush yarn can be attributed to its several distinct advantages over traditional yarns and fibers:

Toothbrush yarn is known for its exceptionally soft texture, making it ideal for fabrics that come into contact with the skin. Whether used in clothing, towels, or upholstery, the yarn provides a high level of comfort and tactile appeal.

Despite its softness, toothbrush yarn is highly durable and resistant to wear and tear. It retains its shape and color even after prolonged use, making it an excellent choice for products that require long-lasting performance.

Toothbrush yarn is often made from recycled polyester, which makes it an environmentally friendly option for those seeking sustainable materials. The use of recycled plastic helps reduce the demand for virgin resources and lowers the carbon footprint of textile production.

The yarn’s versatility makes it suitable for a wide range of applications, from fashion and home furnishings to industrial textiles. It can be spun into various thicknesses and textures to meet the specific needs of different markets.

Like many synthetic fibers, toothbrush yarn is resistant to moisture, which makes it particularly useful for products like towels, wipes, and mats. Its moisture-wicking properties ensure that these products remain dry and comfortable during use.