In the modern textile industry, new fiber materials that are both functional and aesthetic are receiving more and more attention. As an innovative textile raw material, Doped Dyed Polyester Loop Yarn has gradually become a popular choice in the industry with its unique properties and wide application areas.

Production process and technical features

Doping treatment

During the production process, functional additives are evenly incorporated into the polyester fiber. These additives can give the yarn specific properties, such as anti-ultraviolet, antibacterial, antistatic or flame retardant properties. Unlike surface coatings, doping treatment makes the function more durable and less likely to fail due to washing or friction.

Dyeing process

Dyeing is an important part of the yarn. Due to the high crystallinity of polyester fibers themselves, traditional dyeing methods are difficult to achieve the desired coloring effect. Therefore, high temperature and high pressure dyeing technology or disperse dyes are usually used to ensure uniform and strong colors. In addition, some high-end products also use the solution dyeing method, that is, pigments are directly added during the spinning stage to further improve color stability.

Loop pile structure molding

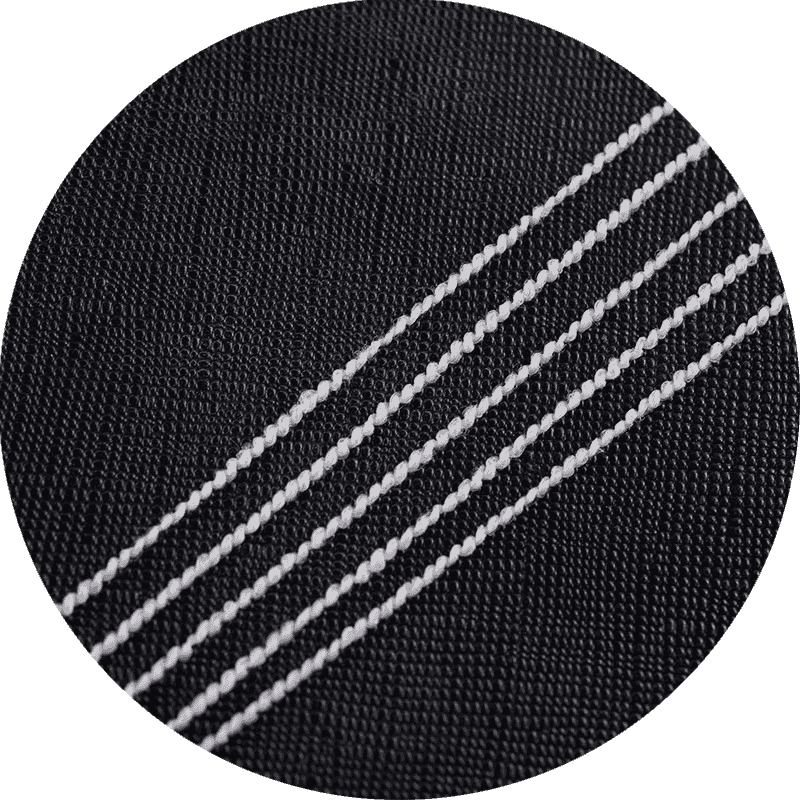

The uniqueness of loop pile yarn lies in the regular or irregular "loop-like" structure on its surface. This structure can be formed by mechanical stretching, heat setting or other physical means. The presence of loop pile not only increases the three-dimensional sense and touch of the yarn, but also enhances the moisture absorption, breathability and warmth retention of the fabric.

Advantages of doped dyed polyester loop pile yarn

Versatility

Double dyed polyester loop pile yarn combines multiple advantages, which can meet basic textile needs and have additional functions. For example, the anti-ultraviolet function makes it suitable for outdoor products; the antibacterial property is suitable for medical and sanitary fields; and the conductive property can be used to produce antistatic work clothes.

Environmental protection and sustainability

With the improvement of environmental awareness, many companies have begun to develop recyclable or low-pollution polyester fibers. The doped dyeing process reduces the use of chemical reagents in the post-finishing process, while extending the service life of the product, thereby reducing resource waste.

Dual visual and tactile experience

The loop pile structure gives the yarn a rich texture and soft feel, making it visually and tactilely attractive. Whether it is used for clothing or home decoration, it can bring a high-end quality experience.

Durability and easy maintenance

Polyester has excellent strength and abrasion resistance, and it remains durable even after doping and dyeing. At the same time, this yarn is easy to clean and maintain, which is very suitable for the fast-paced modern lifestyle.

Application areas

Dyed polyester loop yarn is widely used in many fields due to its diverse properties:

Apparel industry

This yarn is often used to make sportswear, casual wear, coats and sweaters. Its loop structure provides additional warmth, while the doping function enhances the anti-UV or antibacterial properties as needed, providing consumers with more comprehensive protection.

Home decoration

In home furnishings such as curtains, carpets and sofa covers, doped polyester loop yarn can create a luxurious visual effect while combining practicality and durability.

Automotive interior

Modern cars have increasingly higher requirements for interior materials. Dyed polyester loop yarn is widely used in seat covers, ceilings and floor mats due to its soft touch, stable color performance and functionality.

Technical textiles

In the industrial field, this yarn can be used to produce filter materials, protective clothing and special fabrics. For example, yarn doped with conductive particles can be used to make antistatic work clothes to ensure worker safety.

Market Prospects and Challenges

As consumer demand for personalized and functional textiles grows, the market for doped and dyed polyester loop fleece yarn is expected to continue to expand. However, this field also faces some challenges:

Cost Issues

Functional dopants and complex processes may lead to higher production costs, which in turn affect market price competitiveness.

Technological Innovation

How to develop more new dopants and how to optimize loop fleece structures to adapt to different application scenarios are still urgent issues for the industry.

Environmental Regulations

Increasingly stringent environmental regulations around the world require companies to reduce pollutant emissions during the production process, which puts higher requirements on equipment upgrades and technological improvements.

Doped and dyed polyester loop fleece yarn is becoming a star product in the textile industry with its versatility, excellent durability and unique decorative effects. From clothing to home furnishings to industrial uses, its application range continues to expand, injecting new vitality into all walks of life. Despite the challenges of cost and technology, this innovative material will surely usher in a broader development space with the advancement of science and technology and the promotion of market demand. In the future, doped dyed polyester loop velvet yarn is expected to achieve breakthroughs in the direction of intelligence and environmental protection, bringing more convenience and better experience to human life.